Tue March 27, 2018

Crane Equipment Guide

TEXRail is a 27.2 mi. commuter rail system that will operate between downtown Fort Worth, Texas, in Tarrant County and DFW International Airport. Contract for the project was awarded to joint-venture Archer Western-Herzog for $998 million. Davis Motor Crane Service of Irving, Texas, was selected as the contractor for bridge beam placement.

“We needed a solution for a 250-ton class crane that could walk with a load. Multiple rail closures and tight setups also meant that we could not use a crane that needed the time and space to set outriggers. The final requirement was a crane that gave us the necessary headroom clearance under existing overpasses,” said Wes Dowd, operations superintendent of Davis Crane Service.

“Adding the TCC-1100 was an eye opener to the telecrawler market for us. We quickly saw the advantages. So when the TCC-2500 came available we did our homework and checked and double checked our measurements and added it to our fleet. We feel that both of these cranes really give us an advantage to deliver on the unique hoisting needs of our customers,” said Dowd.

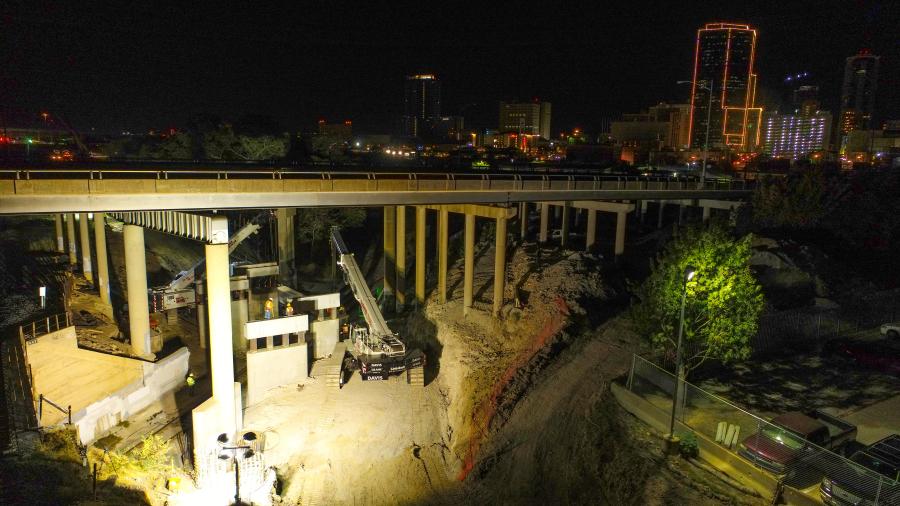

Peach Yard

“We first began in Peach Yard, just northeast of downtown Fort Worth, and worked south from Chocktaw Bridge setting beams parallel to the existing BNSF and Union Pacific line,” said Dowd.

“We first began in Peach Yard, just northeast of downtown Fort Worth, and worked south from Chocktaw Bridge setting beams parallel to the existing BNSF and Union Pacific line,” said Dowd.

Tandem picks were made with two Link-Belt telescopic crawler cranes: the 250-ton (230-t) TCC-2500 and 110-ton (100-t) TCC-1100. The cranes lifted at a steady pace of 16 beams per day on four consecutive days in order to complete the section adjacent to Peach Yard. Right-of-way space required by existing rail companies meant that Davis Cranes had a narrow boundary zone to setup, unload and place the 90 ft. (27.4 m) long, 98,000 lb. (44,452 kg) beams.

“We started out with trucks coming in here close to the rail with the TCC-1100 and TCC-2500 tying into the beams. Because of the small road we had to coordinate how to get the cranes in here, position with the trucks, and then set the beams,” said Lucas Williams, Davis Cranes TCC-2500 operator. “The TCC-2500 is easy to operate; multiple list charts come in handy where we may be flat one minute and then 1, 2 or 3 degrees off the next move around these pier caps.”

Segment 2

The 27.2 mi. project has been broken down into three sections with Segment 2 considered the most tedious and difficult and also the shortest — less than 4 mi. in length. Segment 2 begins at the existing Texas and Pacific Station and winds through downtown stopping at the ITC Station. From there it passes through a highly technical spot called the “hole in the wall” where four Union Pacific and Burlington Southern Santa Fe rail lines and eight lanes of TX 280 all intersect. After that it travels north up to Peach Yard before crossing Choctaw Bridge and east over the Trinity River.

“Of the three segments Segment 2 is easily the most complicated,” said Joseph Coke, quality control inspector of joint-venture Archer Western-Herzog.

“Taking into account the existing right of way from the other rail companies, crossing multiple bridges — both over and under, and adding to that maneuvering around existing utilities to form foundations for the piers in spots where the rail is elevated — this stretch north of downtown has kept us busy,” said Coke.

"Hole in the Wall"

Placing new beams for TexRail below eight lanes of TX 280, parallel to and above active Union Pacific rail lines may have been more appropriately dubbed “threading the needle.” In order to place four 68 ft. long, 120,000 lb. concrete box beams below TX 280 and above an active Union Pacific rail line meant first closing the Union Pacific line for a four hour window from 4 a.m. to 8 a.m.

Placing new beams for TexRail below eight lanes of TX 280, parallel to and above active Union Pacific rail lines may have been more appropriately dubbed “threading the needle.” In order to place four 68 ft. long, 120,000 lb. concrete box beams below TX 280 and above an active Union Pacific rail line meant first closing the Union Pacific line for a four hour window from 4 a.m. to 8 a.m.

“They backed the beams down the hill as far as they could over the tracks and then I scoped out with the TCC-2500 and the TCC-1100 grabbed hold on his side as we lifted up,” said Williams.

Williams and Davis Crane Service had a very tight margin of room to work from with the overhead bridge at 48 ft. (14.6 m) above grade and the newly built pier caps at 22 ft. (6.7 m).

“We worked together to lift up, suck in, boom up and track back so that we could clear the caps to get the booms set because we had probably five or six feet of head clearance on top by the time we got the beams on top of the caps. The beams had to be set in about two and a half hours so the contactor could come in and pull the boards off the rails,” said Williams.

According to Williams one of the most difficult parts of the “hole in the wall” job was actually travelling down the makeshift road to get down into the hole.

“It was a really tight fit, and I didn't have a whole lot of room to maneuver back and forth on my end. That's why we put the bigger crane on my side so that I could reach across the tracks and grab the beams. The TCC-1100 had a little bit more room to walk back and forth if he had to. Pretty much once I got down in there I could only travel about 10 feet forward and backwards,” said Williams.

“I've always been impressed with Link-Belt's crawlers. Their lower has always been stout. I've run some other cranes and their torque won't climb up hills or get through soft spots like these Link-Belts do.

For more information, visit www.linkbelt.com.

Cranes Equipment

Cranes Equipment Articles

Articles Email Updates

Email Updates Sell Your Machines

Sell Your Machines

Cranes Equipment

Cranes Equipment Cranes Dealers

Cranes Dealers Cranes Articles

Cranes Articles Email Updates

Email Updates Sell Your Machines

Sell Your Machines